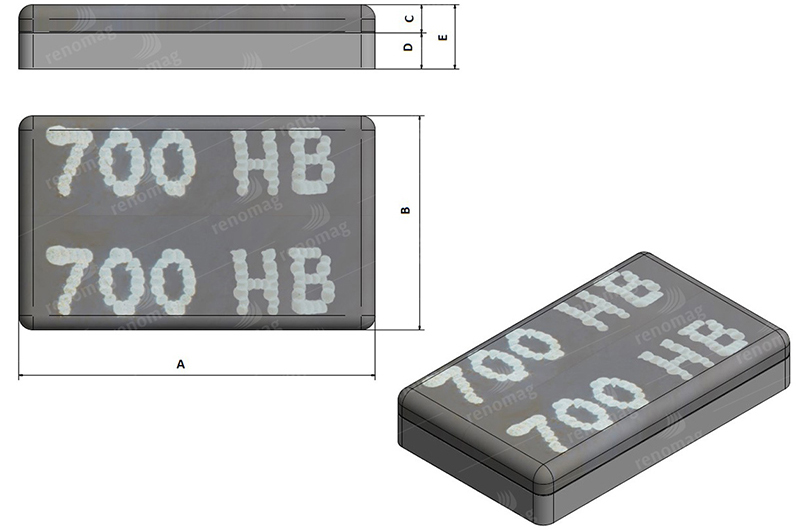

Two-part chromium carbide blocks 700 HB

Speed and wear rate due to abrasion depend on working conditions of the machine, the mined material, temperature and a way of work. In order to minimize the loss of material due to abrasion there are plates from abrasion resistant steel used for the construction of excavator an loader buckets. These sheets are mainly 400, 450 and 500 HB hardness with several times higher wear life and toughness in comparison with ordinary structural materials. In some cases even this level of protection is not sufficient, or it is needed to reduce the machine downtime due to repairs. Especially for these cases we supply various products from composite materials containing chromium carbides. These products provide a creative, effective and inexpensive solution for the protection of abrasion strained machine parts, where their service life in comparison with hardened plates is many times higher.

Composite materials in a block put on the material with good weldability are highly abrasion resistant with hardness above 700 HB. They are supplied in a wide range of shapes and sizes.

- all the blocks have 700 HB hardness

- they contain hard chromium carbide bound in the matrix put on the weldable base panel

- all parts are magnetic due to iron content

- suitable even for the operation in temperatures above 700 °C

Two-part composite materials of the most preferred sizes are promptly supplied right from our warehouse. A broad range of other products can be shipped in a short time thanks to our cooperation with the leading world manufacturers in the industry.

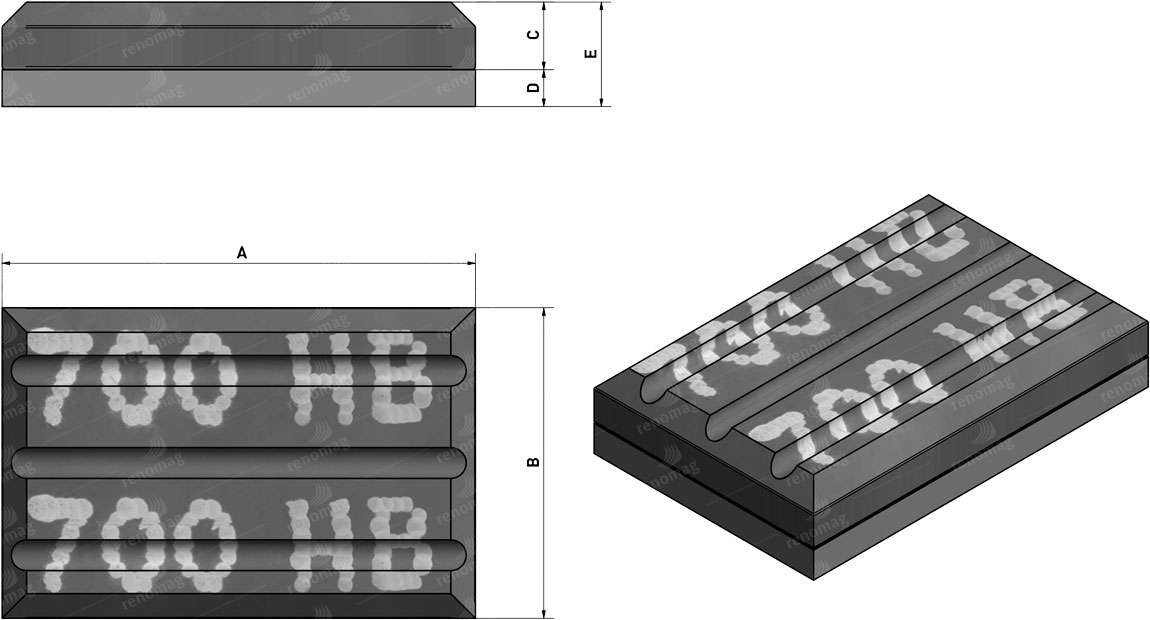

Perforated blocks (“chocolates”)

We offer unique abrasion resistant mouldable perforated blocks (chocolate bars) in many sizes with a highly variable use. They can be bent and placed onto curved surfaces and due to perforation they are also easily divided with a grinder for adjustment to the needed size. They will be mainly utilized for the abrasive wear protection on excavator buckets, loader buckets, on action parts of hammers, jaws and crusher inlets, or in many other industrial applications.

- resembles the shape of a chocolate bar

- material layer with high hardness and abrasion resistance is in the upper pyramidal part

- a block of ‟chocolate bars” can be welded onto a base as a unit or gradually – like a chocolate bar – one bar by another, the lower layer can also be mildly bent, which only adds to the diversity of its use

| RENOMAG code |

Size (mm) | Dimension (mm) | Wieght (kg) | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| XRC25 | 240 × 25 × 23 | 240 | 25 | 15 | 23 | 0.9 |

| XRC40 | 240 × 40 × 23 | 240 | 40 | 15 | 23 | 1.5 |

| XRC50 | 240 × 50 × 23 | 240 | 50 | 15 | 23 | 1.9 |

| XRC65 | 240 × 65 × 23 | 240 | 65 | 15 | 23 | 2.5 |

| XRC80 | 240 × 80 × 23 | 240 | 80 | 15 | 23 | 3.2 |

| XRC90 | 240 × 90 × 23 | 240 | 90 | 15 | 23 | 3.5 |

| XRC100 | 240 × 100 × 23 | 240 | 100 | 15 | 23 | 3.9 |

| XRC130 | 240 × 130 × 23 | 240 | 130 | 15 | 23 | 5.4 |

| XRC150 | 240 × 150 × 23 | 240 | 150 | 15 | 23 | 6 |

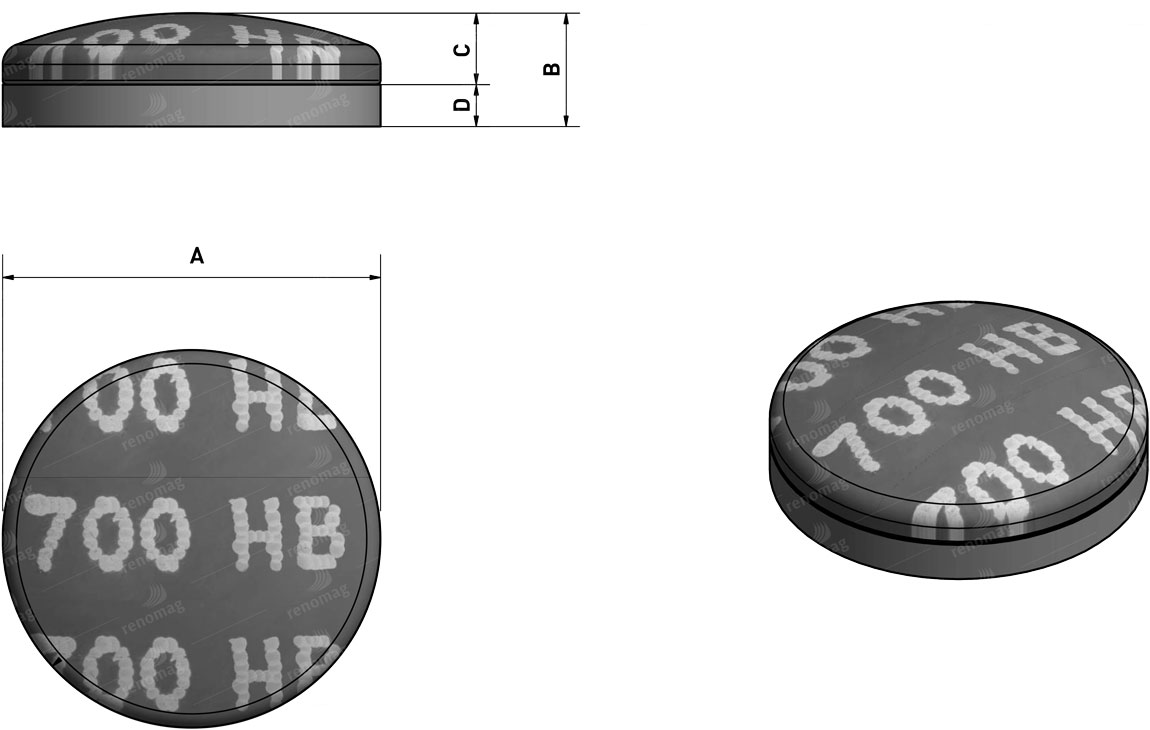

Round blocks (“buttons”)

The round shape guides material flow, a convex surface diverts the direction of abrasion effect and it is impact resistant. Available in several sizes for easy choice fitting the size of the surface that it will protect against abrasion with high efficiency. The most frequent is the application on the sides of excavator buckets and loader buckets for quarrying.

- a round vaulted shape with a facet which provides maximum abrasion protection and diverts the effects of impacts

- if welded on this model is ideal for minimizing the risk of possible crack formation in base material

- it is designated particularly for excavator buckets

- the button shape element has a thick material layer on it with high hardness and abrasion resistance put on the round basic weldable material as the top coronet

| Označení RENOMAG | Size (diameter × height) mm | Size (mm) | Weight (kg) | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| XRB60 | 60 × 27 | 60 | 27 | 17 | 10 | 0.7 |

| XRB75 | 75 × 27 | 75 | 27 | 17 | 10 | 0.8 |

| XRB90 | 90 × 27 | 90 | 27 | 17 | 10 | 1.4 |

| XRB110 | 110 × 32 | 110 | 32 | 20 | 12 | 2.1 |

| XRB115 | 115 × 32 | 115 | 32 | 20 | 12 | 2.5 |

| XRB150 | 150 × 41 | 150 | 41 | 25 | 16 | 5.7 |

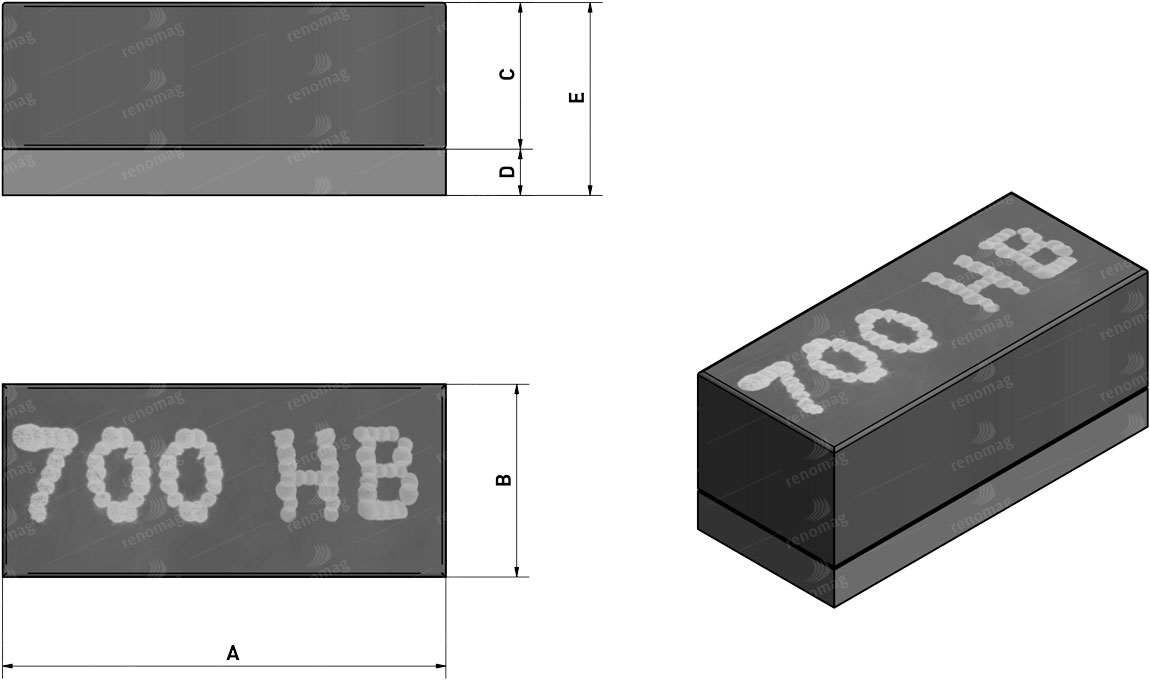

Rectangular blocks

Rectangular blocks with a high layer of abrasion resistant material will be put to best use where there is relatively low impact strain and installation on a flat surface is possible (not bendable). They can be used e.g. on the side edges of loader buckets moving bulk abrasive material and in other similar applications.

- prism shape with a massive layer of abrasion resistant material

- serves as an additional protection in a high abrasion environment with a relatively low impact strain on flat surfaces (not bendable)

- this high hardness and abrasion resistant material is applied on a thin weldable lower side of an ashlar

| RENOMAG code |

Size (mm) | Dimension (mm) | Weight (kg) | ||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||

| XRS200A | 200 × 25 × 25 | 200 | 25 | 15 | 10 | 25 | 1.0 |

| XRS300A | 300 × 25 × 25 | 300 | 25 | 15 | 10 | 25 | 1.5 |

| XRS115 | 115 × 50 × 50 | 115 | 50 | 38 | 12 | 50 | 2.3 |

| XRS150A | 150 × 50 × 50 | 150 | 50 | 40 | 10 | 50 | 2.9 |

| XRS230 | 230 × 50 × 50 | 230 | 50 | 38 | 12 | 50 | 4.5 |

| XRS432 | 432 × 50 × 50 | 432 | 50 | 38 | 12 | 50 | 8.5 |

| XRS150B | 150 × 75 × 39 | 150 | 75 | 29 | 10 | 39 | 3.4 |

| XRS150C | 150 × 75 × 50 | 150 | 75 | 40 | 10 | 50 | 4.4 |

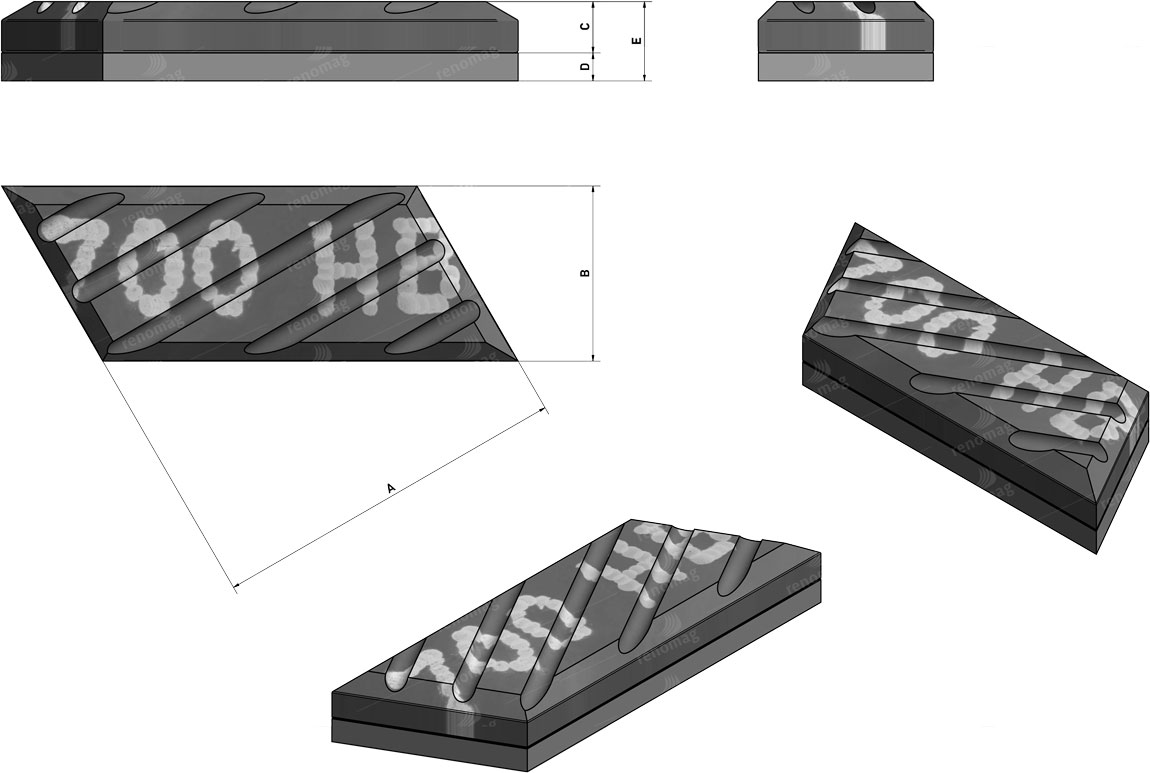

Plate blocks (friction type)

Plate blocks for abrasion protection will prove their worth especially in protecting large flat surfaces in places where strong friction and wear by abrasive material occurs.

- they are an excellent choice for large surfaces suchas bottoms and sides of rock mining buckets, truck bodies and dumpers, the sides of bulldozer blade mounts

| RENOMAG code |

Type | Size (mm) | Dimension (mm) | Weight (kg) | ||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | ||||

| XRD1-214 | 1 | 214 × 101 × 34 | 214 | 101 | 22 | 12 | 34 | 5.1 |

| XRD1-302 | 302 × 101 × 34 | 302 | 101 | 22 | 12 | 34 | 7.3 | |

| XRD1-154 | 154 × 101 × 34 | 154 | 101 | 22 | 12 | 34 | 3.7 | |

| XRD1-279 | 279 × 75 × 34 | 279 | 75 | 22 | 12 | 34 | 6.1 | |

| XRD2-214L | 2 | 214 × 101 × 34 | 214 | 101 | 22 | 12 | 34 | 5.9 |

| XRD2-214R | 214 × 101 × 34 | 214 | 101 | 22 | 12 | 34 | 5.9 | |

| XRD2-302L | 302 × 101 × 34 | 302 | 101 | 22 | 12 | 34 | 8.4 | |

| XRD2-302R | 302 × 101 × 34 | 302 | 101 | 22 | 12 | 34 | 8.4 | |

| XRD2-154L | 154 × 101 × 34 | 154 | 101 | 22 | 12 | 34 | 4.2 | |

| XRD2-154R | 154 × 101 × 34 | 154 | 101 | 22 | 12 | 34 | 4.2 | |

| XRD3-250A | 3 | 250 × 150 × 45 | 250 | 150 | 20 | 25 | 45 | 13.1 |

| XRD3-200 | 200 × 150 × 45 | 200 | 150 | 20 | 25 | 45 | 10.5 | |

| XRD3-250B | 250 × 250 × 45 | 250 | 250 | 20 | 25 | 45 | 21.9 | |

TYPE 1

TYPE 2

TYPE 3

All types of abrasion resistant blocks can also be supplied in sizes based on your specific requirements.