Renomag Rubber Tracks

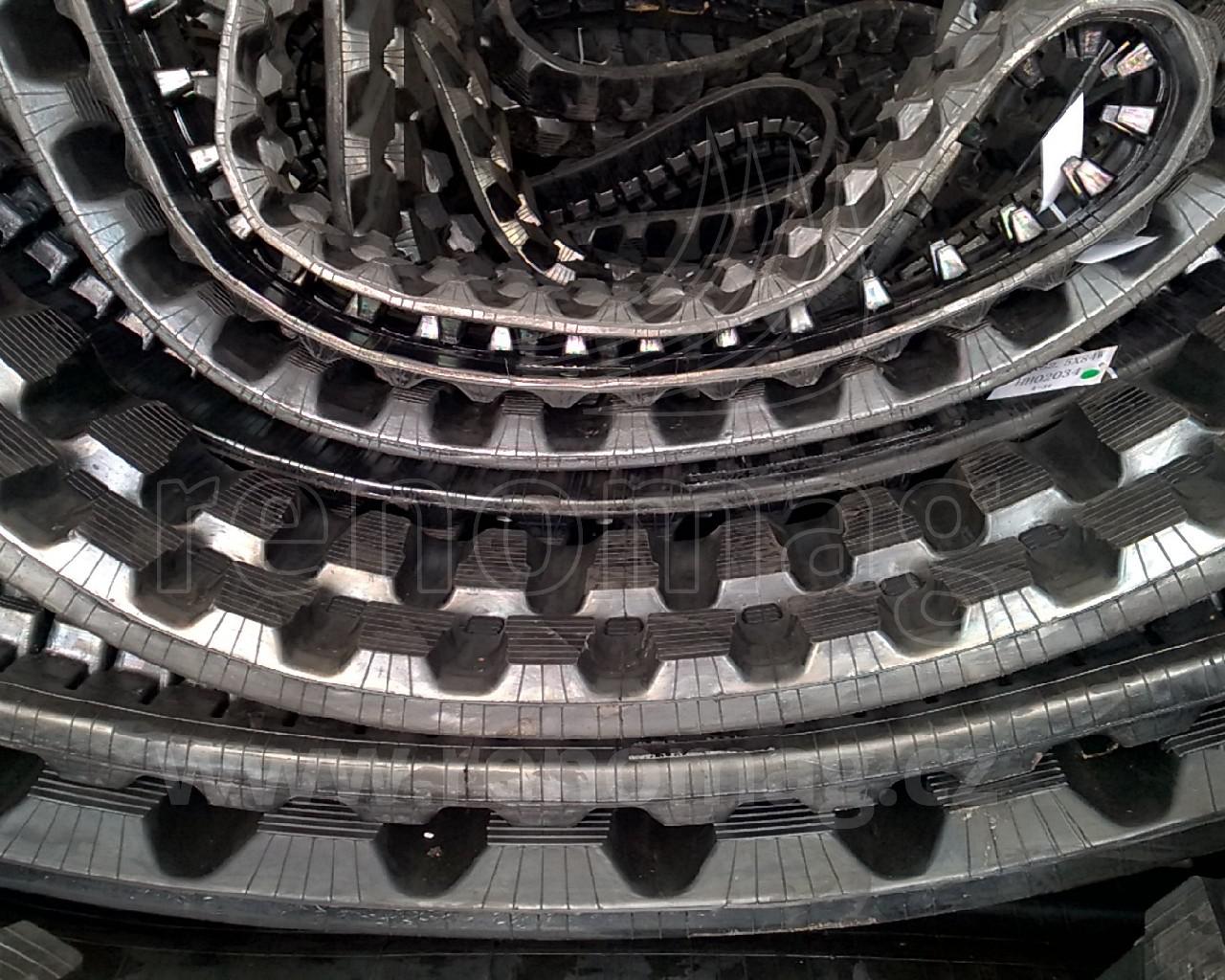

We offer operators and owners of the small construction machinery quality durable rubber tracks Renomag for the economically favorable and reliable operation. Manufactured in a ISO 9001-2015 certified plant on the basis of the latest knowledge in the industry and using state-of-the-art technologies. Our program includes a wide variety of rubber tracks with interesting prices for micro, mini and midi, excavators as well as for tracked skid steer loaders, dumpers and other machinery. In some sizes we alternatively also provide tracks in anti-vibration or reinforced design with additional external lock for for even better holding a trace.

Why you should purchase from us?

Why you should purchase from us?

- Our mission is to offer the best possible quality at the lowest guaranteed prices of rubber tracks made in accordance with the OEM standards for primary manufacturers, with ISO 9001-2015 certificate; we never deliver the cheapest recycled rubber products

- As we have been operating in the industry of construction machinery and rubber tracks for more than 30 years, you can rely on us to always obtain the right size for your specific machine, including engineering consultancy

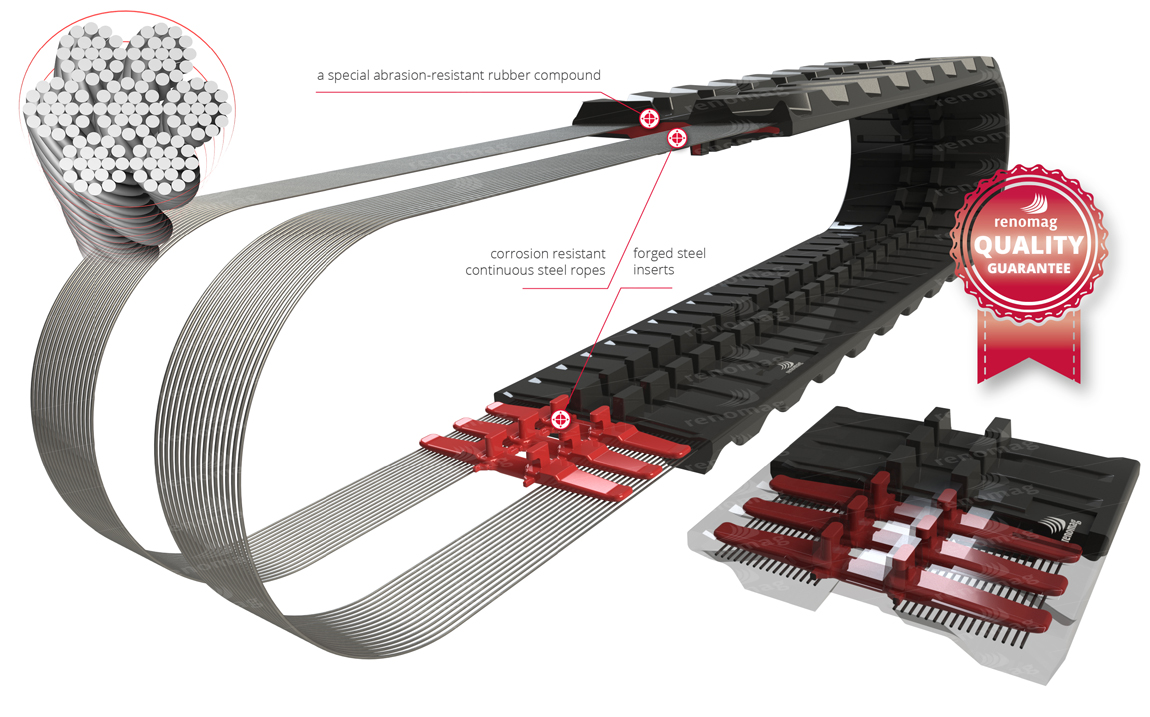

- The products delivered by us have corrosion-resistant continuous wire ropes and forged steel inserts built in their sturdy framework in order to ensure firmness and resilience in demanding operation conditions

- Rubber tracks are made from a special rubber compound resistant to abrasive wear with longer service life than afforded by natural rubber; a particular layer provides UV protection

- We know that the speed of the delivery is always very important, that’s why we have prepared a wide range of quality tracks in our warehouse for machines of a variety of makes; in addition to regular shipments on working days we are ready to deliver, based on prior telephone arrangement, at any time as per customers' needs

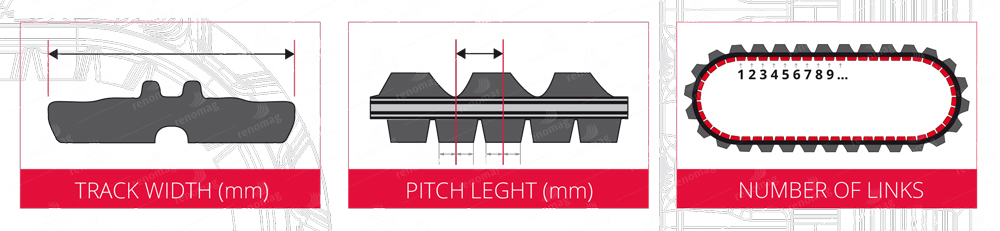

How to determine the right size of rubber track?

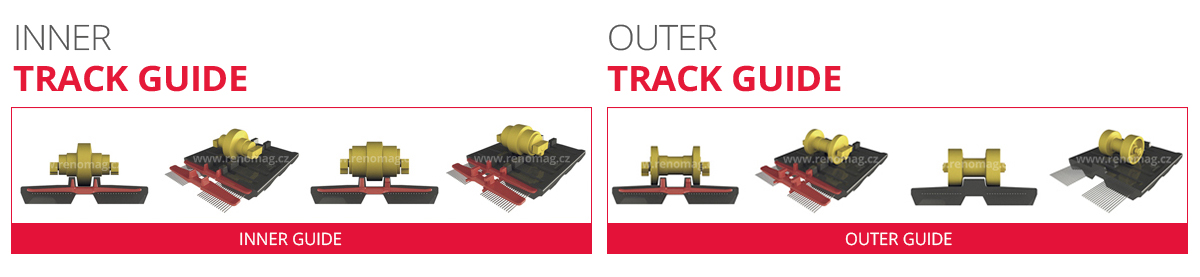

Rubber track size can be easily determined by tread width, pitch length and number of links (metal inserts). We recommend contacting our technical department to determine the correct type according to the internal construction and the type of guiding in the undercarriage.

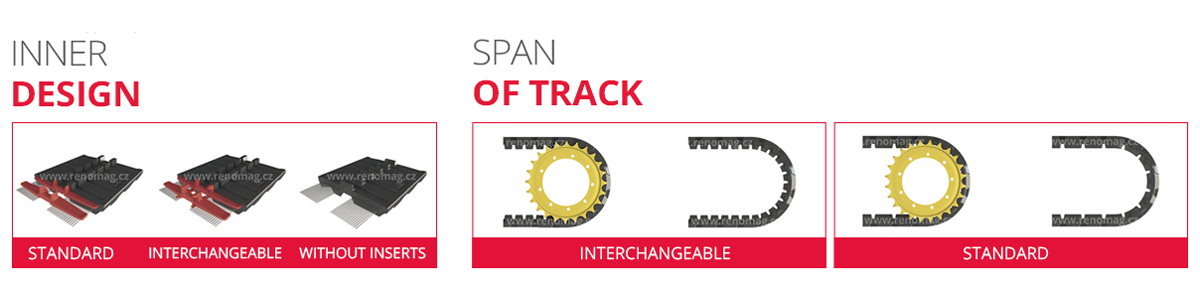

What are the types of guiding, construction and pitch of rubber tracks?

What machines can Renomag rubber parts be used for?

The quality of the rubber tracks delivered by us, their service life, excellent traction, low noise and vibration resistance can be used for machine undercarriages of these producers:

AICHI, AIRMANN, ANTEC, ATLAS, ATLASCOPCO, AVANT TECNO

BARALDI, BARETTA, BELLE, BENATI, BENFRA, BENNY, BERTANI, BOBCAT, BONNE ESPERANCE, BROOK

CAMISA, CANYCOM, CARMIX, CARRIER, CASE, CATERPILLAR, CATO, CHIEFTAN, CHIKUSUI, CME, COMECA, COMET, COMET-IMECA, CORMIDI

DAEWOO, DODICH, DRAGO, DYNAPAC

ECOMAT, EUROCAT, EUROCOMACH, EURODIG, EUROTOM, EUROTRACH

FAI, FERCAD, FERMEC, FIAT-HITACHI, FRESIA / RAMPICAR, FUJI, FURUKAWA

GEHL, GEHLMAX, GRILLO

HAINZL, HANIX, HCC, HINOWA, HITACHI, HOKUETSU, HOLMAC, HONDA, HS PENTA, HUKI, HUTTER, HYDROMAC, HYUNDAI, IBEA

IHI, IMECA, IMEF, IMER, ISEKI, IWAFUJI

JCB, JOHN DEERE

KAIDI, KATO, KOBELCO, KOMATSU, KUBOTA

LIBRA

MACMOTER, MASSEY FERGUSON, MAWECO, MAXIMA, MBU, MEINZ MUCK, MESSERSI’, MINICARRIER, MINIDIG, MINITRACK, MITSUBISHI, MOROOKA, MULTIDRILL

NAGANO, NEUSON, NEW HOLLAND, NISSAN, NOZAWA

OCTOPUSSY, ORENSTEIN & KOPPEL, ORMAC

PALAZZANI, PAZZAGLIA, PEL-JOB, PENTAMOTER, PICCINI, POWERFAB

RAPID, ROCK, ROSSI, ROTAIR

SAMSUNG, SANDQUEEN, SATO, SCATTRACK, SCHAEFF, SEDIDRIL, SHIN-TOWA, SILLA, SUMITOMO

TADANO, TAKEUCHI, TANAKA, TEKNA, TERRA JET, TEUPEN

UNIMOV, UTEX

VENIERI, VOLVO

YAMAGUCHI, YANMAR, YASHIMA, YGRY, YUCHAI

ZAVATTINI, ZEPPELIN

... and more.

How should rubber tracks be maintained to achieve their longest possible life?

- Always make sure to keep the right stretch of the track based on the machine manual

- Periodically inspect and in case of excessive wear replace in time other undercarriage parts (top rollers, track rollers, idlers, tension units and sprockets), they significantly influence tracks' life

- Avoid using machines with rubber tracks on surfaces with sharp stones and driving across debris from demolitions, they can destroy the track

- If the oil or other lubricant gets spilled on surface of the rubber track, clean it immediately

- Minimize acting of sunlight on rubber part as much as possible

- The track as well as other undercarriage parts should be regularly cleaned. When material accumulates in the undercarriage space, this will reduce the correct functioning of the idlers tension units and lead to rupturing of the track

- Avoid fast turns and abrupt changes of the drive direction, in particular on rough terrain