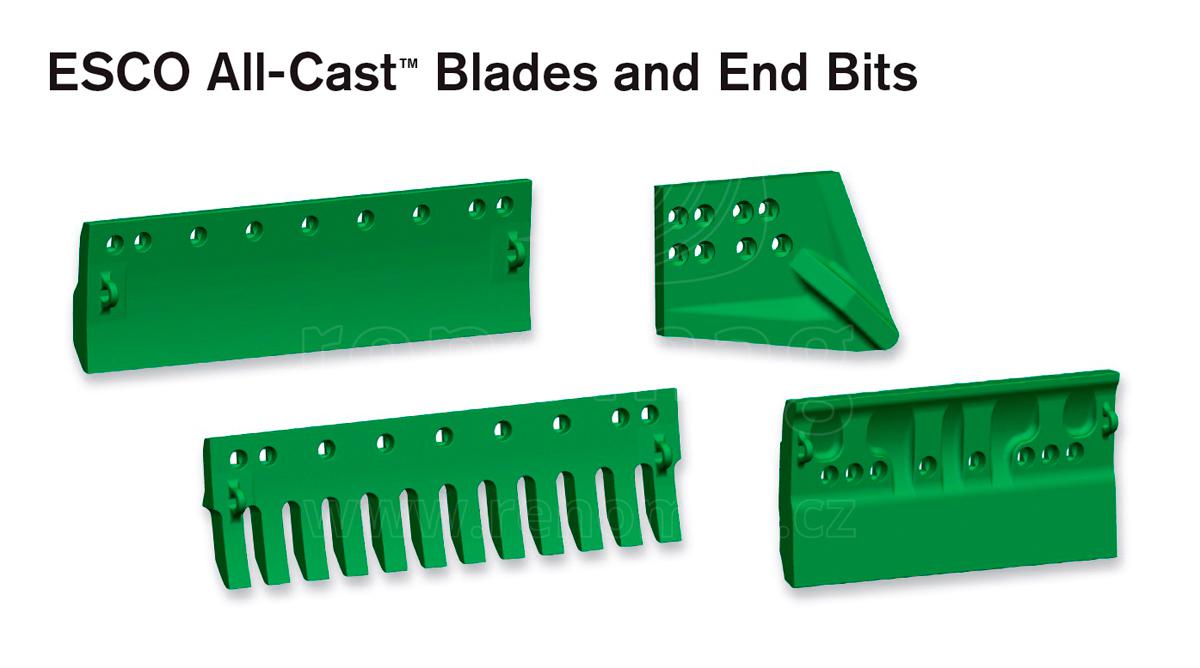

Esco All-Cast dozer edges

Given that operating bulldozers during mining and on the construction site is one of the most demanding operations, the ESCO® company developed all-cast dozer edges and end bits for bulldozers. They are available for the most models of the popular brands CAT® and Komatsu® above 280 Ps (from size CAT® D8 and Komatsu® D155 and bigger). All-cast dozer edges are designed to fit every model and fulfill requirements for providing ideal performance.

What is the difference between All-Cast cutting edges and end bits?

Contrary to the standard edges made from rolled steel where holes for screws and bevels are machined, the shape of ESCO® castings including edges and holes is originated in pouring metal to the mould. This process allows usage of durable hardened alloy and addition of steel where it needs to be added.

Advantages of ESCO® Solution

- Thanks to the right placement of metal, there are shorter time periods for essential interruption of operation including lesser maintenance expenses

- ESCO® steel alloys 12S, 514 BHN provide greater hardness with unrivalled impact resistance and abrasive wear.

- It provides greater durability for the edges, which decreases maintenance expenses and increases productivity

- Minimization of break risk keeps the machine constantly in operation

D11 Comprehensive Offer

Besides standard All-Cast dozer cutting edges and end bits, ESCO® provides an offer for CAT® D11 bulldozer ploughshare with even greater advantages:

- End bits have, in comparison with the normal version, 16% more material, distributed to attain even abrasion wear

- Angular edges have, in comparison with the normal version, 56% more material

- Abrasion resistant metal is situated in spots where it achieves optimal firmness and durability for every use of the bulldozer itself

- ESCO edge solution for D11 enables increased safety and easier installation; there are derrick loops on all parts

- Machined contact surfaces provide a balanced distribution of load