Shrouds of the edge and sides

Wear through abrasion on excavator and loader buckets in operation first occurs particularly on the parts between teeth on the edge and on the lower part of the sides. The period without a need of costly repairs and the ensuing downtime of equipment can be extended when an additional shrouds is mounted to protect the active elements and prevent early wear or even failure and consequent breaking of the edge. Due to their shape, the side covers will further facilitate penetrability and increase the speed of the work cycle. In both cases the service life of the construction machinery attachments is significantly prolonged through the distribution and facilitation of impact wear absorption.

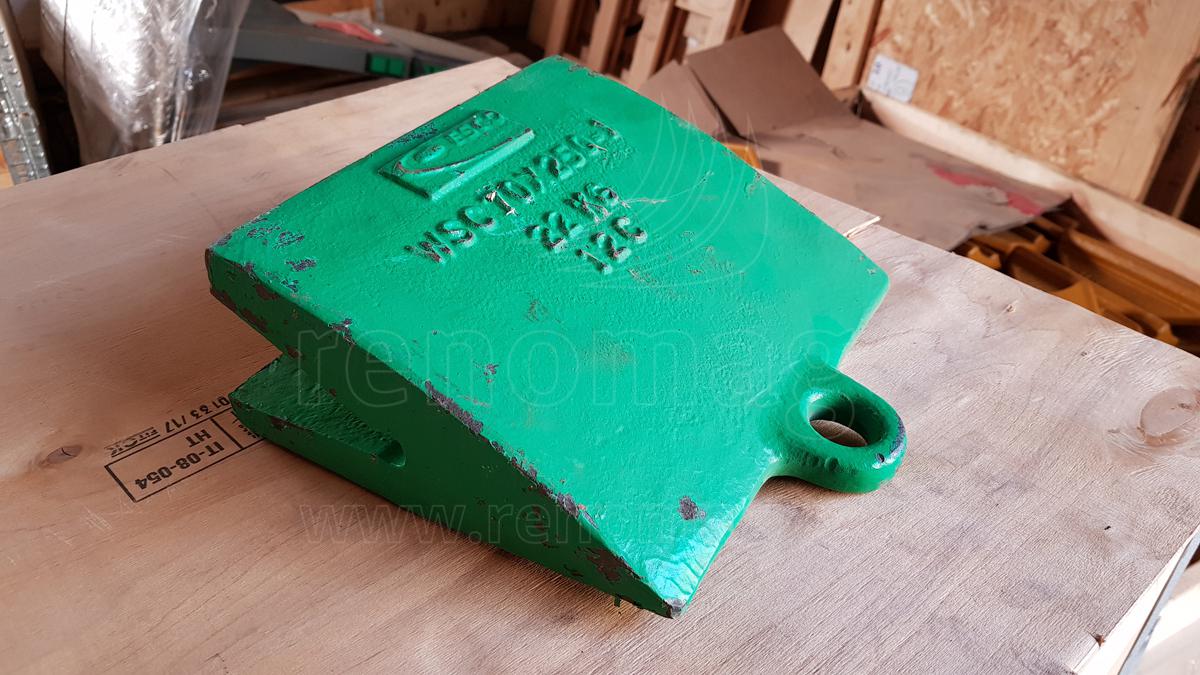

We keep a permanent stock of a wide range of casings of various designs, which can be welded or bolted onto the equipment, or ESCO® Toplok® products from premium alloys which provide for easy, safe and swift replacement without using a hammer.

We will gladly consult with you the choice fitting just your conditions and propose the best suited solution. Especially when it comes to larger-size construction and mining machinery, installation of abrasion resistant shrouds is reflected into minimizing the maintenance cost, reducing downtimes, through improvement of penetration it saves tyres, wear of the boom and fuel consumption.