Esco Nemisys tooth system for mining machines

ESCO® was founded in Portland, Oregon, in 1913. For over a hundred years now the company has seen steady customer demand for its products in order to increase their productivity and make use of ESCO®'s professional services and innovative solutions to their vexing problems regarding wear and tear, impacts, corrosion and insufficient thermal resistance. Present in nineteen countries on six continents, the company operates a network of 28 manufacturing plants and 35 sale points and distribution centres.

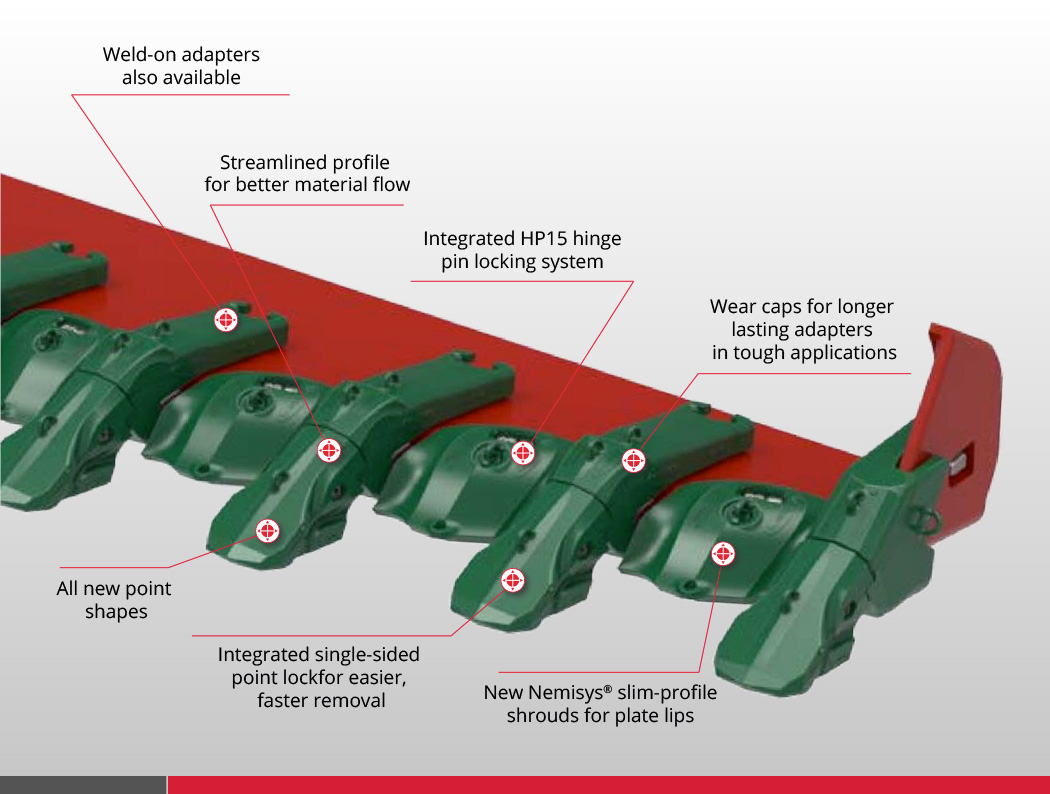

Esco® Nemisys® is an advanced and cost-effective tooth system that responds to the specific needs of excavator and wheel loader users in the demanding conditions of mining operations.

LOWER YOUR COST PER TON WITH THE ESCO® NEMISYS®

Proven and effective.

With over 750 installations worldwide, ESCO® Nemisys® lip and G.E.T. system is field proven to lower operating cost per ton. Wheel loaders with more than 4,000 hours of testing and verification has proven significant benefits for mining operations.

With over 750 installations worldwide, ESCO® Nemisys® lip and G.E.T. system is field proven to lower operating cost per ton. Wheel loaders with more than 4,000 hours of testing and verification has proven significant benefits for mining operations.

PROVEN BENEFITS OF THE ESCO® NEMISYS®

Increased machine availability

- Superior alloys and optimized system profile result in longer-lasting components

- Simple, intuitive locks provide safer, faster parts replacement

- Reliability and wear life unmatched in the industry keeps machines operating with minimal downtime

- Unrivaled reliability and longevity in the industry achieves machine operation with maximum economy

Lower maintenance costs

- Proprietary alloy, increased lip protection and large bearing areas extend operating intervals

- Longer lasting and more reliable G.E.T. reduces planned and unplanned service events

- Quick and easy parts replacements by fewer crew members, with no hot-work required

BRINGS IMPROVEMENT FOR THE OPERATION OF WHEEL LOADERS AND EXCAVATORS

The Nemisys® wheel loader system can be installed on a range of common blade thicknesses and bevel angles, covering CAT® 992, Komatsu® WA800 and larger.

Adapters and teeth for excavators can be used ranging from size ranges such as Komatsu® PC1100, Hitachi® EX1200, Liebherr® R9100 to machines with a weight class of approx. 800 tons intended for rock mining.

PRODUCTIVITY

- Best-in-class wear life to weight ratio allows you to move more material per set of teeth with the Nemisys® system

CONFIGURATIONS TO MEET ALL YOUR NEEDS

- The Nemisys® system for wheel loaders is compatible with OEM and ESCO® Loadmaster® lip configurations across a range of lip thicknesses

THE NEXT GENERATION OF NEMISYS® SHROUDS

- Lighter than comparable shrouds

- Integrated lock

- SecureLift™ enabled for safer replacement

Esco® Nemisys® Lip System for Wheel Loaders (1,5 MB)

Esco® Nemisys® Cast Lip Systems for Mining Excavators, Face Shovels and Dragline Buckets (2 MB)