Abrasion Wear Protection

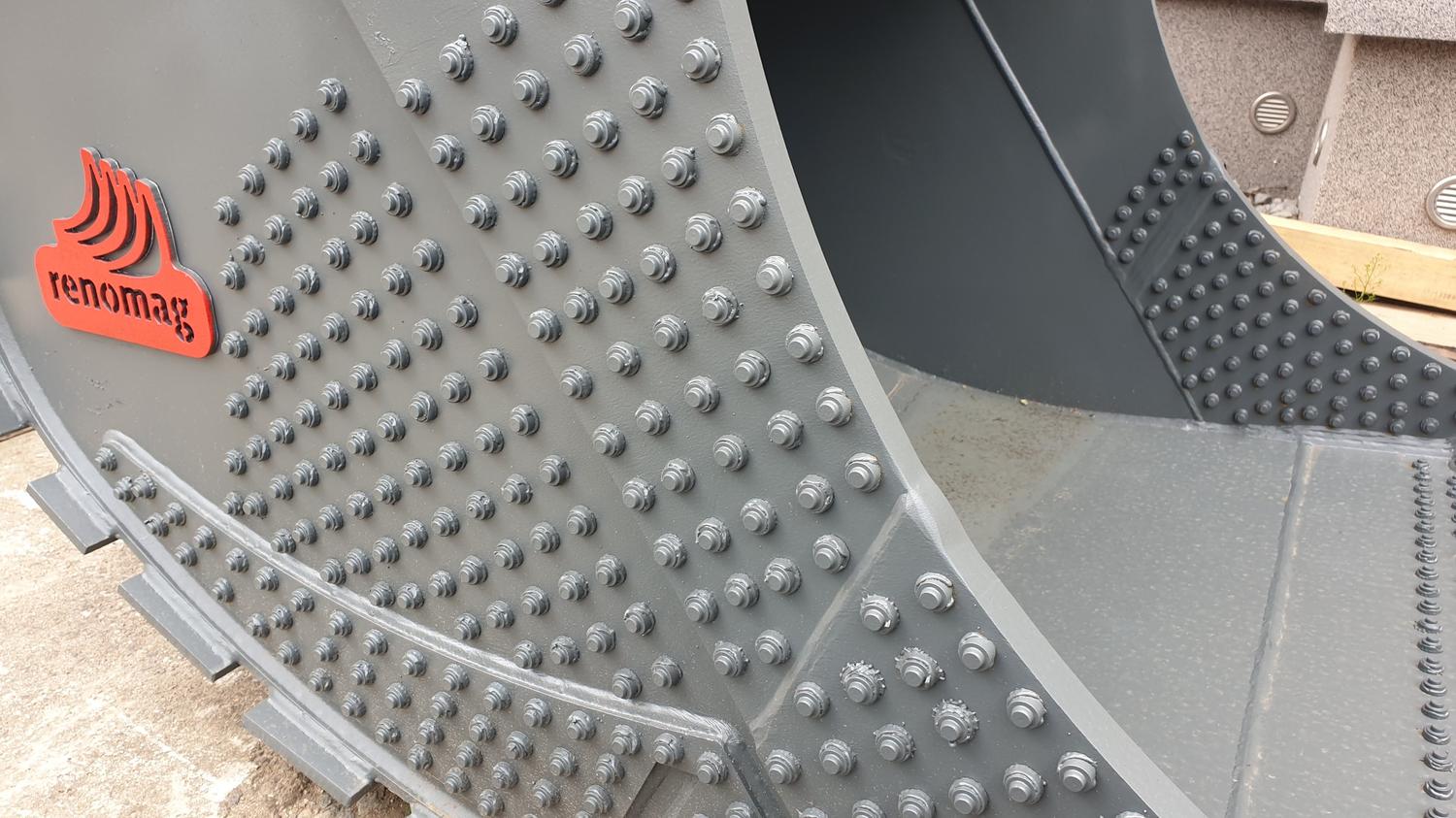

We offer protection of attachment of your construction and mining machines in conditions with the extreme abrasion wear. This procedure, which aims to increase the service life of tools like excavator bucket, loader bucket, front shovel, bulldozer blades, drill, ripper and a lot of others, is executed primarily using the mobile service right in the customer’s premises.

We can use these two methods or their combination:

- welding-on of coated metal sheets or two-part blocks - this solution is suitable for level surfaces or slightly curved surfaces whereon the final hardness will reach 700 HBN;

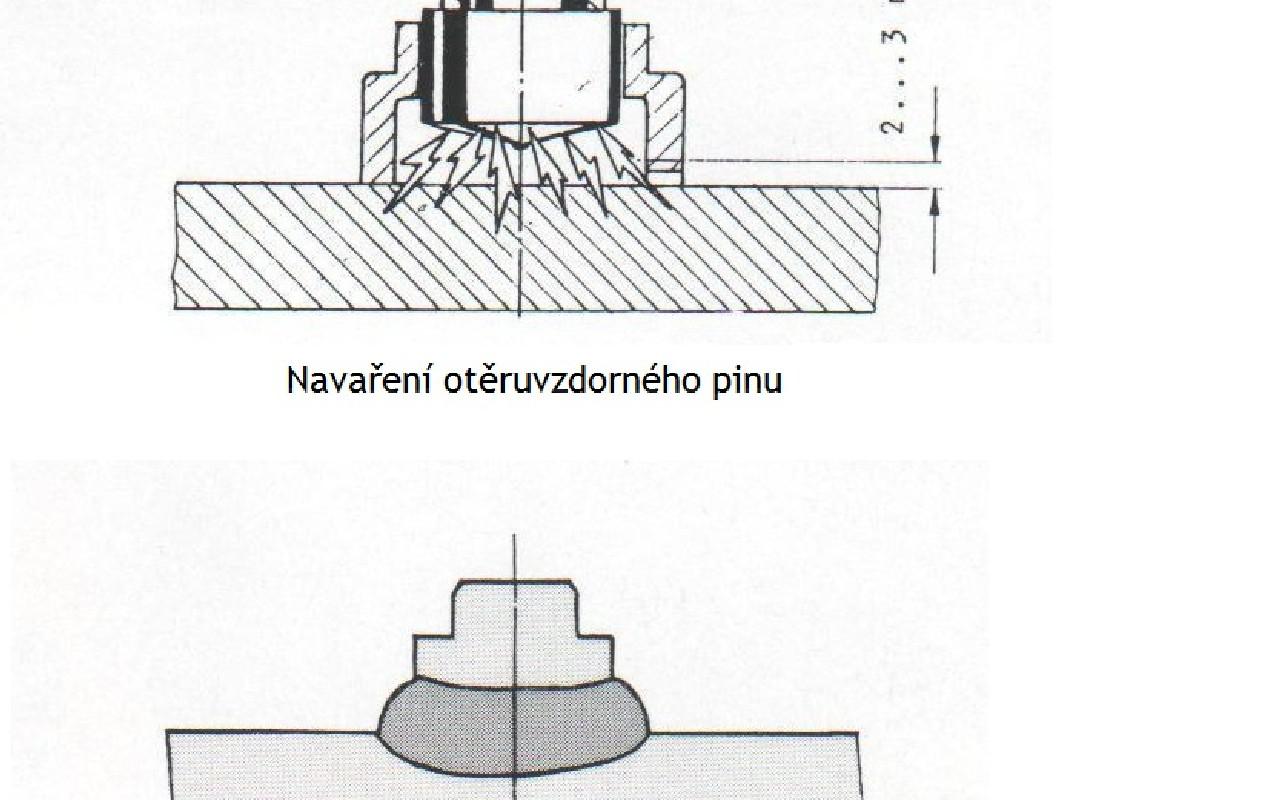

- welding-on of abrasion-resistant pins (60 HRC) or pins with an 80 HRC insert made of tungsten carbide - this solution is appropriate for spots exposed to minor impacts and can also be used for curved surfaces. Ideally suited for buckets and augers as used in sandpits, kaoline quarries and similar operations where the mined material forms a layer between the rows of pins.

The advantage of these solutions in comparison with the standard welding by the abrasion resistant electrode is faster execution, minimum heat impact on the base material and many times longer service life.